TWO-STAGE PM VSD AIR COMPRESSOR SERIES (TPTT-V)

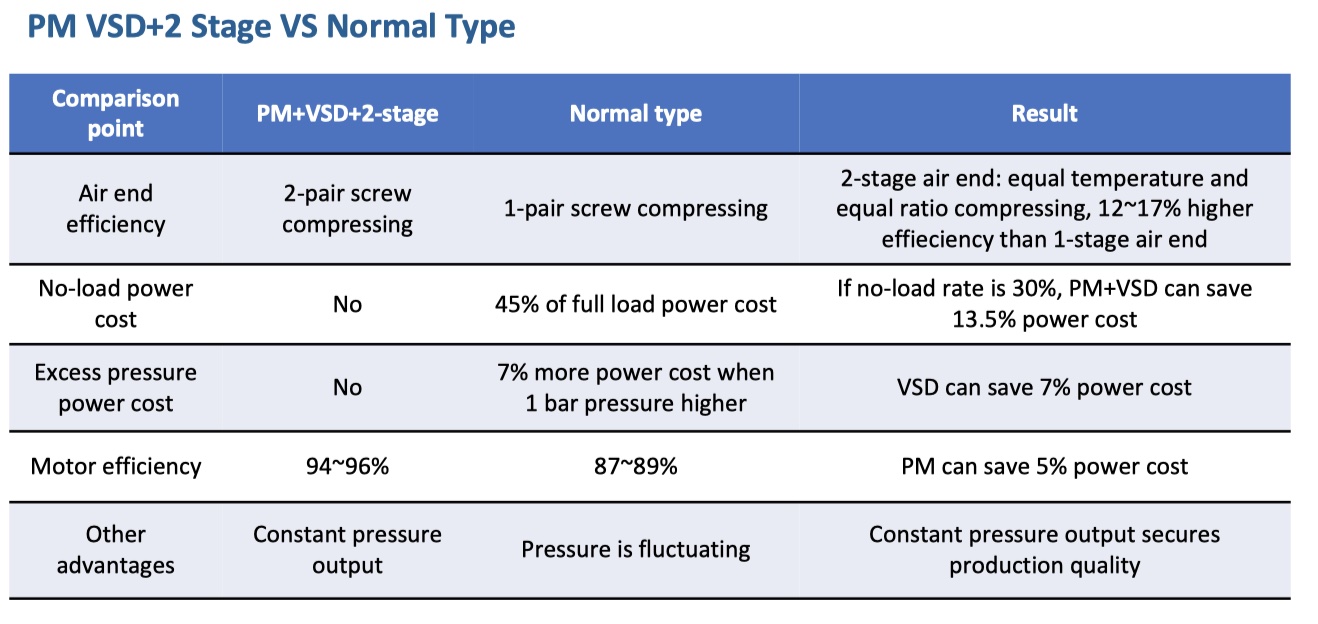

Compared to single-stage compressors, a two-stage is much closer to isothermal compression. This is achieved by the injection of fresh oil between the stages which reduces the inlet temperature to the second stage. This lower inlet temperature increases efficiency by reducing the compression ratio between the stages. In addition, leakage between the rotor seals is significantly reduced resulting in outstanding volumetric efficiency.

- Two-stage air compressors are closer to the ideal isothermal compression

- Reduced leakage increases volumetric efficiency

- Saves 10-15% of energy compared to single-stage compressors

- Increases flow by 10-15% compared to single-stage compressors

- Lower pressure differential increases efficiency and reliability

- Low heat load ü Easy maintenance and service

- Lowest life cycle cost of any compressor on the market

|

Model

|

Working pressure

|

Capacity

|

Power

|

Noise

|

Air outlet pipe diameter

|

Net weight

|

Dimensions(mm)

|

|

bar

|

m³/min

|

kW

|

hp

|

dB

|

kg

|

Length

|

Width

|

Height

|

|

TPTT-37V

|

8

|

2.3-7.7

|

37

|

50

|

65±3

|

G2

|

1800

|

1860

|

1180

|

1430

|

|

10

|

1.9-6.9

|

37

|

50

|

65±3

|

G2

|

1800

|

I860

|

1180

|

1430

|

|

13

|

/

|

37

|

50

|

65±3

|

G2

|

1800

|

1860

|

1180

|

1430

|

|

TPTT-45V

|

8

|

3.2-10.5

|

45

|

60

|

65±3

|

G2

|

2000

|

1860

|

1180

|

1430

|

|

10

|

2.2-7.8

|

45

|

60

|

65±3

|

G2

|

2000

|

1860

|

1180

|

1430

|

|

13

|

2.5-6.1

|

45

|

60

|

65±3

|

G2

|

2000

|

1860

|

1180

|

1430

|

|

TPTT-55V

|

8

|

3.9-13.2

|

55

|

75

|

65±3

|

G2

|

2450

|

2160

|

1350

|

1750

|

|

10

|

3.1-10.7

|

55

|

75

|

65±3

|

G2

|

2450

|

2160

|

1350

|

1750

|

|

13

|

2.6-8.8

|

55

|

75

|

65±3

|

G2

|

2450

|

2160

|

1350

|

1750

|

|

TPTT-75V

|

8

|

5.0-16.8

|

75

|

100

|

68±3

|

G2

|

2550

|

2160

|

1350

|

1750

|

|

10

|

4.1-13.8

|

75

|

100

|

68±3

|

G2

|

2550

|

2160

|

1350

|

1750

|

|

13

|

3.6-12.3

|

75

|

100

|

68±3

|

G2

|

2550

|

2160

|

1350

|

1750

|

|

TPTT-90V

|

8

|

6.0-20.1

|

90

|

120

|

70±3

|

DN65

|

3250

|

2420

|

1530

|

1720

|

|

10

|

5.2-17.3

|

90

|

120

|

70±3

|

DN65

|

3250

|

2420

|

1530

|

1720

|

|

13

|

4.8-15.9

|

90

|

120

|

70±3

|

DN65

|

3250

|

2420

|

1530

|

1720

|

|

TPTT-110V

|

8

|

7.1-23.5

|

110

|

150

|

72±3

|

DN80

|

3600

|

2650

|

1600

|

1850

|

|

10

|

5.9-19.8

|

110

|

150

|

72±3

|

DN80

|

3600

|

2650

|

1600

|

1850

|

|

13

|

5.3-17.8

|

110

|

150

|

72±3

|

DN80

|

3600

|

265

|

1600

|

1850

|

|

TPTT-132V

|

8

|

8.0-28.1

|

132

|

175

|

74±3

|

DN80

|

3700

|

2650

|

1600

|

1850

|

|

10

|

7.3-24.3

|

132

|

175

|

74±3

|

DN80

|

3700

|

2650

|

1600

|

1850

|

|

13

|

6.1-20.2

|

132

|

175

|

74±3

|

DN80

|

3700

|

2650

|

1600

|

1850

|

|

TPTT-160V

|

8

|

10.1-33.6

|

160

|

215

|

75±3

|

DN100

|

4250

|

3350

|

1900

|

1950

|

|

10

|

9.2-30.5

|

160

|

215

|

75±3

|

DN100

|

4250

|

3350

|

1900

|

1950

|

|

13

|

8.4-28.0

|

160

|

215

|

75±3

|

DN100

|

4250

|

3350

|

1900

|

1950

|

|

TPTT-185V

|

8

|

12.4-38.7

|

185

|

250

|

76±3

|

DN100

|

4650

|

3350

|

1900

|

1950

|

|

10

|

10.4-34.8

|

185

|

250

|

76±3

|

DN100

|

4650

|

3350

|

1900

|

1950

|

|

13

|

9.7-32.3

|

185

|

250

|

76±3

|

DN100

|

4650

|

3350

|

1900

|

1950

|

|

TPTT-200V

|

8

|

12.8-42.6

|

200

|

270

|

76±3

|

DN100

|

5550

|

3350

|

1900

|

1950

|

|

10

|

12.2-40.5

|

200

|

270

|

76±3

|

DN100

|

5550

|

3350

|

1900

|

1950

|

|

13

|

10.6-35.1

|

200

|

270

|

76±3

|

DN100

|

5550

|

3350

|

1900

|

1950

|

|

TPTT-220V

|

8

|

14.2-47.3

|

220

|

300

|

78±3

|

DN100

|

5650

|

3700

|

2060

|

2150

|

|

10

|

12.8-42.5

|

220

|

300

|

78±3

|

DN100

|

5650

|

3700

|

2060

|

2150

|

|

13

|

12.0-37.4

|

220

|

300

|

78±3

|

DN100

|

5650

|

3700

|

2060

|

2150

|

|

TPTT-250V

|

8

|

18.5-52.8

|

250

|

350

|

78±3

|

DN100

|

6450

|

3700

|

2060

|

2150

|

|

10

|

15.1-48.3

|

250

|

350

|

78±3

|

DN100

|

6450

|

3700

|

2060

|

2150

|

|

13

|

13.3-43.0

|

250

|

350

|

78±3

|

DN100

|

6450

|

3700

|

2060

|

2150

|

The exhaust volume is measured under the rated exhaust pressure, according to the national standard GB3853 test (equivalent to ISO1217 appendix C).

Recommend frquency 30%-100%.

The above data is based on the standard grid- 380V/ 50HZ.

Please make further inquiry for the non-standard specification type and machines which are used under high/low temperature, high humidity, dusty working environment.