Air Compressor for Food and Fruit

Food Grade Air Compressor

Compressed air is widely used in the food industry and is the main source of power.

For example, in many fruit and vegetable processing plants, compressed air systems are used for container cleaning, sorting, cutting, shaping, filling, and packaging systems. In bakeries, we use compressed air to blow off bread crumbs. For the snack food, we use compressed air to generate nitrogen, which is used to purge the ambient air from the packaging bag.

When choosing an air compressor for the food or beverage industry, we concern most is the contamination problem, to ensure dry and clean compressed air for your production line. Your food needs to meet rigorous safety inspections.

We can provide TUV Class 0 Oil-free compressed air for the food industry.

Do you need

Class 0 Oil-free compressed air systems for your Contact food processing line?

|

|

Do you need

oil-lubricated compressors for your non-contact low-risk food line?

|

| CONTACT US |

|

We have more than 30 years’ experience.

|

Typical Applications for Food Compressor

|

Item

|

What are the Common Applications for Food Safe Compressors?

|

|

Sorting

|

In many fruit and vegetable processing plants, compressed air is used to power control valves and other pneumatic systems in the automatic sorting equipment.

|

|

Transporting

|

For powdered products or raw materials, we use compressed air to push them through pipes, such as flour, milk powder, cocoa powder, and so on.

|

|

Peeling and cutting

|

To peel fruit and vegetables, such as garlic, onions. To peel the shells of nuts. Clean and efficient. The compressed air with high pressure can also be used for cutting food.

|

|

Filling

|

During the processing of pastries, cakes, cookies, pies, and other baked food, we need to use compressed air to fill the delicious paddings into them.

For the liquid such as drinking pure water, beverage, juices, milk, beer, cooling oil, also use compressed air to fill into the bottles or bags.

|

|

Cooling

|

Baked food needs to be cooled down when leaving the oven, guarantee the quality and flavor of your food, and it also can be packaged more quickly. The air knives for cutting or peeling, also need to be cooled in the production line.

|

|

Mixing

|

Using compressed air to mix dry food can be clean, efficient, and avoid damage.

|

|

Packaging

|

For glass bottles, generally, we use 3~4bar low pressure to blow, and for PET plastic bottles, we use 30~40bar high pressure to blow. For some PP plastic bottles, we usually use less than 10bar pressure to blow.

|

|

Cleaning

|

For food containers, such as cans, bottles, bags, boxes, compressed air can be used for cleaning before filling.

|

|

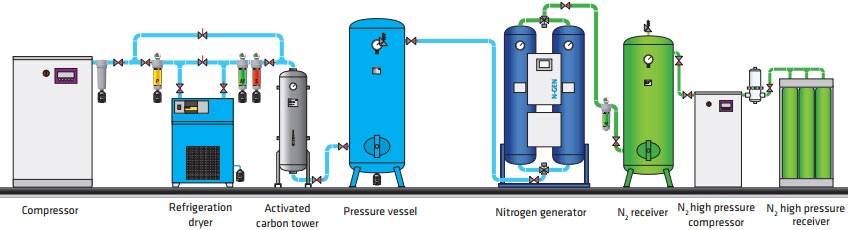

Nitrogen Generation

|

The air compressor can be used for nitrogen generation.

Packaging for snack food, such as chips and shrimp strip, use nitrogen gas to prevent the product from being crushed

Nitrogen is often used in the storage of foods and beverages, such as purging oxygen from the packages to prevent oxidation affecting product quality and flavor. Nitrogen can also be used in the modified atmosphere packaging (MAP); the inert atmosphere in food packages is critical to ensure long life.

|

|

Spraying

|

Compressed air is used to blow crumbs off of bread in a commercial bakery.

|

|

Fermentation

|

Supply oxygen to bacteria, produce food ingredients such as citric acid, wine, yogurt.

|

Quality Requirements for Food Compressor

In the food industry, the compressed air should be purified of contaminants before use.

General contaminants are solid particulates, water vapor, and moisture, oil vapors. Which are in the atmospheric air, the lubricating oil for oil-injected type air compressor, the pipes, storage air tank, and distribution.

When the compressed air has a direct connection with the food products, we must ensure purity and cleanliness to prevent contamination. For the details what we should do are as follows:

Remove the moisture

As we know, moisture is good for microorganisms and fungus growth. If there is moisture inside the pipes of the compressed air, it is easy to be blown to the food products or the packaging or containers. Besides, compressed air with moisture can also cause microbial on the food. So we need to use dryers to ensure the required dew point. Generally, for the direct contact compressed air, the dew point should be -40℃ and use a desiccant air dryer, and for low-risk non-contact compressed air, the dew point can be 3℃ and use a refrigeration air dryer.

Remove the oil

The oil exists in the atmospheric air, so even you choose a 100% Oil-free type air compressor, there is still oil vapor in the compressed air, so the filters should be used. Generally, for direct contact compressed air, use a 100% oil-free type air compressor is a must. For low-risk non-contact compressed air, we can use an oil-lubricated type air compressor which is more economical, but it’s better to use filters to ensure the oil content 0.003ppm.

Remove the particles

The atmospheric air includes solid particulates or dust that may cause contamination if contact with the food products. Other contaminants may come from internal mechanisms of the air compressor system. We also need to use filters to ensure the particle content is no more than 0.01μm.

Common Equipment for the Food Applications

- For the direct contact compressed air for food production line, we suggest using 100% Oil-free type air compressor with the desiccant air dryer and filters, the materials should be used is food-grade stainless steel.

- For the non-contact low-risk compressed air for food production line, if with a limited budget, the oil-lubricated type air compressor with refrigeration air dryer and filters can be chosen, but for long term consideration, an oil-free type air compressor can not only produce high-quality oil-free and clean air but also costs lower for maintenance and energy.