About TyphoonCompressor Refrigerated Air Dryer

In compressed air systems, moisture is a huge problem and the prevention of corrosion caused by condensed water is an important issue. This is a critical factor as moisture and corrosion would minimize the performance and shorten the lifetime of compressed air systems and pneumatically controlled tools and equipment. To prevent this problem from occurring, the air dryer is the most commonly used solution. In these kinds of equipment, the main problems which affect the performance of compressed air systems are high volume, high pressure loss and complicated traditional types of heat exchangers which are not efficient. For this, TyphoonCompressor has successfully integrated the Brazed Heat Exchanger into our dryer system. This technology is supported by complete research and proven test data and the unique design has enabled TyphoonCompressor to obtain is being patented in France, USA, Taiwan and Southeast Asia.

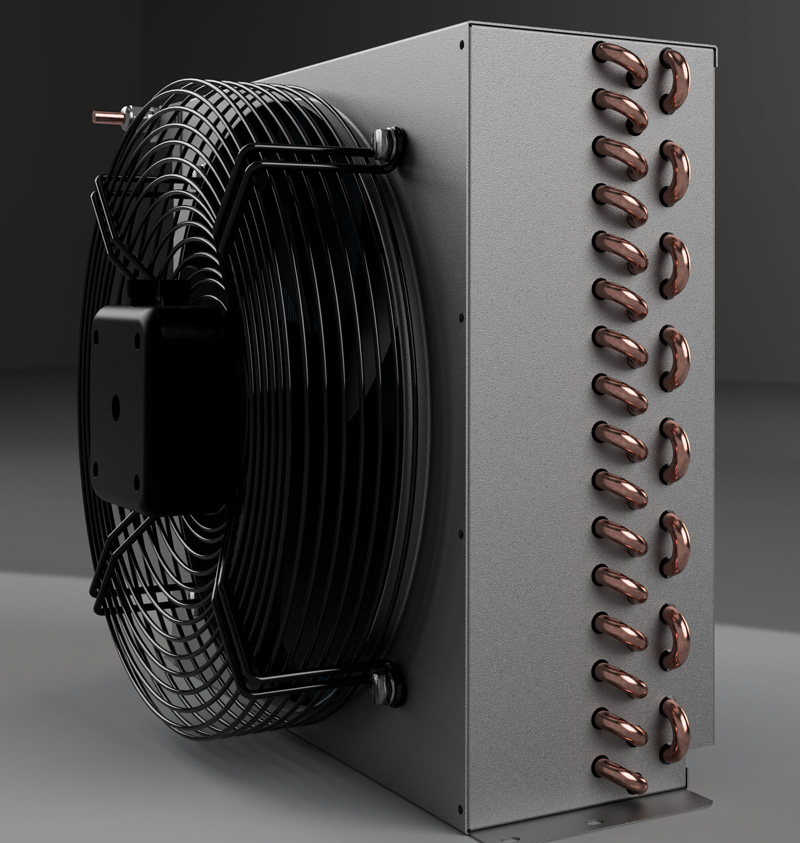

Powerful Condenser

Our refrigerated air dryers offer a reliable, cost effective and simple solution to avoid condensation and corrosion in your systems.

Energy Saving

Fitted with Digital Scroll Compressors which adapt their refrigeration production according to of the thermal load to be dissipated, and allow great energy saving.

Easy to Maintain

On the rare occasion when servicing is needed, the enclosure design allows for direct access to all components allowing for easy maintenance of the dryer.

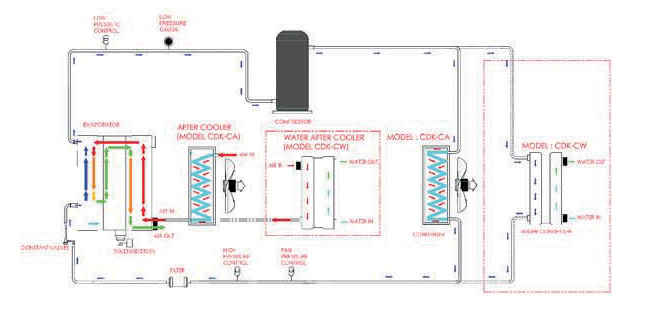

MODEL CDK-CA 175

MODEL CDK-CA 175

1. UL/CE Condenser Fan

Provide qualified cooling fans with UL/CE safety certification for long using life.

2. Easy to Operate CAREL Control Panel

The advance digital display allows TyphoonCompressor's dryer operation to be easily monitored at a glance.

3. High Quality Refrigerant Compressor

Hermetic, suction gas is cooled and protected against thermal and current overloads. the compressor is mounted on anti-vibration rubber supports to ensure quiet running of the dryer.

4. Stainless Steel Plate Heat Exchanger

- UL / CE / PED Certified

- Long life time durability

- Corrosion Resistant

- High Thermal Transfer Efficiancy Compact

- Easy Installation

- Proven and Reliable Quality

- Flexible Flows and Temp / Monitor Option

5. Reliable Solenoid Valve

TyphoonCompressor’s reliable solenoid valve is standard in all models. The discharge and pause timers are adjustable via the CAREL control panel. The flexible and adaptable operation of the valve ensures effective discharge of condensates.

The main advantage of Plate Heat Exchanger

A 3 in 1 configuration, the air-to-air exchanger,evaporators and demister separator are combined in one module.

This ensures a very compact, robust and energy efficient design.

High efficiency heat transfer performance.

Unique patents for cross-flow design features with the condensate being separated as soon as it is created along the cooling path.

Energy saving application due to low pressure drop.

Simple and easy maintenance.

Dry air down to 3 ˚C pressure dew point at outlet

UL / CE / PED Certified

Long life time durability

Corrosion Resistant

High Thermal Transfer Efficiancy

Easy Installation

Proven and Reliable Quality

Flexible Flows and Temp / Monitor Option

Compact

Unique Design Separator

TyphoonCompressor's distinct non-mesh design separator has advantages of lower pressure drop, clogging free, maintenance free, and longer service life than other heat exchangers.

Oil Blockage Free

Patented plate design of evaporator, shorten the flow path of refrigerant by 30%, with the smooth surface of SUS 304, TyphoonCompressor can prevent lubricant oil residual which happens frequently in aluminum plate fin heat exchangers.

No Ice Blockage

With TyphoonCompressor patented plate design of evaporator, condensed water will not remain on the plates, but directly enters to a separation space of the evaporator, which effectively reduce the risk of ice blockage. (Need to check the drain valve regularly).

Equipped with Patented Leakage Testing Connector

Leading and multinational patent technology, exclusively ensures excellent quality of TyphoonCompressor 3-in-1 brazed plate heat exchanger.residual which happens frequently in alumi-num plate fin heat exchangers.

Internal UL/CE After cooler & Condenser Fan

Provide qualified cooling fans with UL/CE safety certification for long using life.

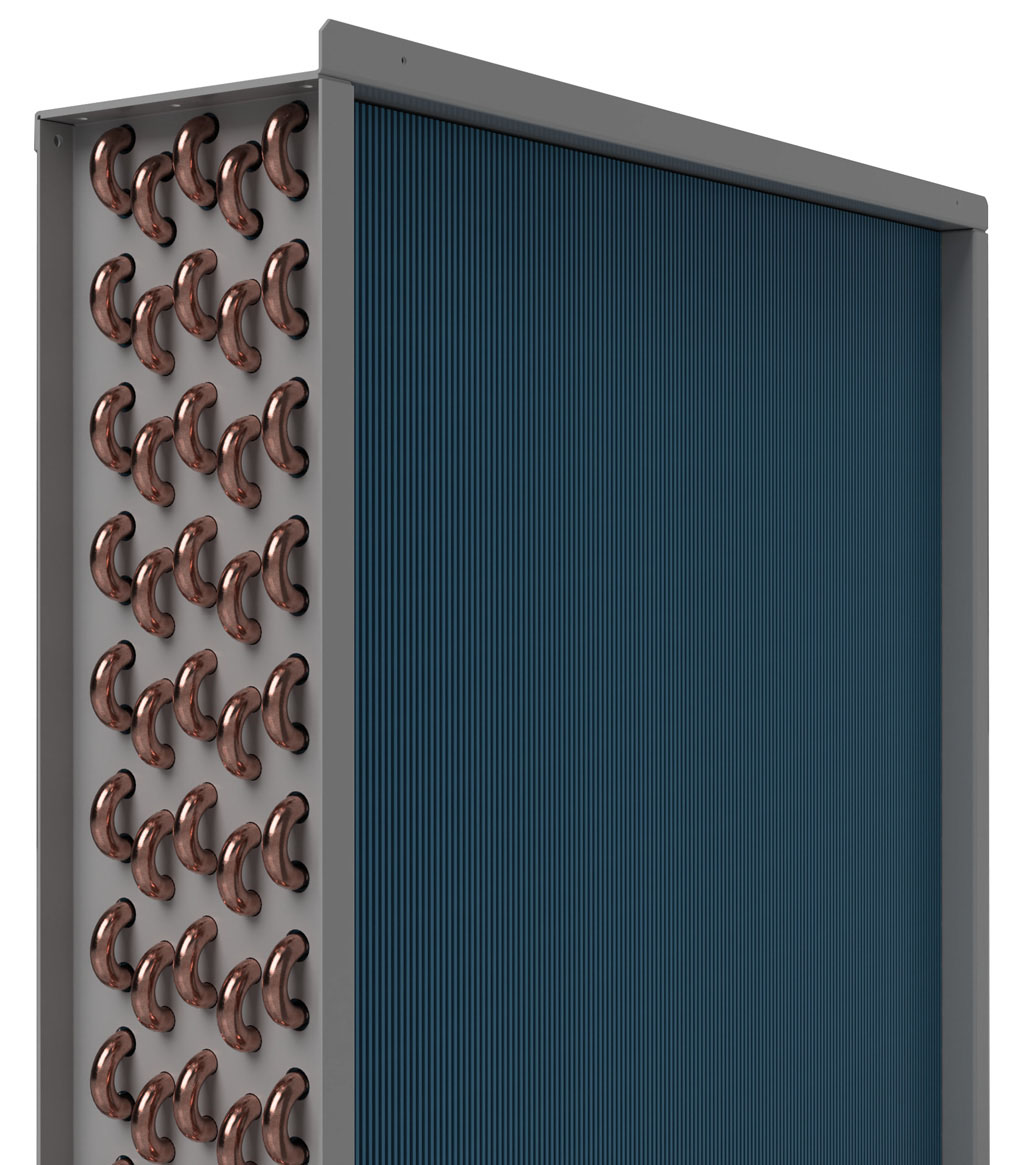

Powerful Blue Fin Air Condenser

TyphoonCompressor’s large surface area heat exchanger contributes to higher performance on our refridgerated air dryers when compaired to other machines on the market.

Our anti-corrosive blue fins protect the condenser coils from different types of corrosion caused due to moisture, humidity, harsh weather conditions.

While improving the heat transfer process and increasing the cooling capacity, The blue-fin technology enhances the durability and longevity of TyphoonCompressor’s Air Dryers.

Easy to Install

TyphoonCompressor's compact design and well-structured component layout provides extreme installation flexibility. The easily accessible components ensure that TyphoonCompressor dryer occupies less valuable plant floor space.

High Quality Refrigerant Compressor

Hermetic, Suction gas is cooled and protected against thermal and current overload. The compressor is mounted on anti-vibration rubber supports to ensure quite running of the dryer.

COPELAND | HITACHI | MITSUBISHI

*Compressor brands vary from model to model.

Reliable Solenoid Valve

TyphoonCompressor’s reliable solenoid valve is standard in all models. The discharge and pause timers are adjustable via the CAREL control panel. The flexible and adaptable operation of the valve ensures effective discharge of condensates.

Easy to Operate CAREL Control Panel

The advance digital display allows TyphoonCompressor's dryer operation to be easily monitored at a glance.

Use for model: CDK 3-250

Use for model: CDK 3-250

Use for model: CDK 300-700

Use for model: CDK 300-700

Use for model: CDK 800 and up

Use for model: CDK 800 and up

Technical Specifications: CDK-CA | Air Cooler

|

MODEL

|

Air Flow

|

Power Supply

|

Nominal

|

Connection |

Dimension (mm)

|

Weight

|

Refrigerant

|

Pressure

|

| (m³/min) |

(CMF) |

V/PH/Hz

|

Power (kw)

|

inch |

W.

|

L. |

H.

|

Kg

|

Bar (max)

|

|

CDK-5CA

|

0.65

|

23

|

220/1/50

|

0.24

|

1/2” PT

|

380

|

500

|

750

|

60

|

R134a

|

16

|

|

CDK-8CA

|

0.9

|

32

|

220/1/50

|

0.28

|

1/2” PT

|

380

|

500

|

750

|

65

|

R134a

|

16

|

|

CDK-10CA

|

1.4

|

49

|

220/1/50

|

0.4

|

1” PT

|

388

|

718

|

880

|

80

|

R134a

|

16

|

|

CDK-15CA

|

1.8

|

64

|

220/1/50

|

0.45

|

1” PT

|

388

|

718

|

880

|

88

|

R134a

|

16

|

|

CDK-20CA

|

2.7

|

95

|

220/1/50

|

0.6

|

1-1/2” PT

|

388

|

718

|

880

|

91

|

R134a

|

16

|

|

CDK-30CA

|

4.3

|

152

|

220/1/50

|

0.96

|

1-1/2” PT

|

388

|

868

|

1200

|

97

|

R134a

|

16

|

|

CDK-40CA

|

5.5

|

194

|

220/1/50

|

1.22

|

1-1/2” PT

|

388

|

868

|

1200

|

113

|

R134a

|

16

|

|

CDK-50CA

|

6.8

|

240

|

220/1/50

|

1.42

|

1-1/2” PT

|

388

|

868

|

1200

|

128

|

R407c

|

16

|

|

CDK-60CA

|

8.1

|

286

|

220/1/50

|

1.65

|

2” PT

|

450

|

1200

|

1350

|

137

|

R407c

|

16

|

|

CDK-75CA

|

11

|

388

|

220/1/50

|

1.98

|

2” PT

|

450

|

1200

|

1350

|

150

|

R407c

|

16

|

|

CDK-100CA

|

15

|

530

|

380/3/50

|

3

|

2-1/2” PT

|

600

|

1200

|

1600

|

200

|

R407c

|

16

|

|

CDK-125CA

|

18

|

636

|

380/3/50

|

3.35

|

2-1/2” PT

|

600

|

1200

|

1600

|

230

|

R407c

|

16

|

|

CDK-150CA

|

23

|

812

|

380/3/50

|

4.2

|

2-1/2” PT

|

600

|

1200

|

1600

|

250

|

R407c

|

16

|

|

CDK-175CA

|

28

|

989

|

380/3/50

|

4.85

|

2-1/2” PT

|

600

|

1200

|

1600

|

250

|

R407c

|

16

|

|

CDK-200CA

|

30

|

1059

|

380/3/50

|

5.17

|

3” PT

|

1000

|

1500

|

1850

|

380

|

R407c

|

16

|

|

CDK-250CA

|

36

|

1271

|

380/3/50

|

5.5

|

3” PT

|

1000

|

1500

|

1850

|

420

|

R407c

|

16

|

|

CDK-300CA

|

43

|

1519

|

380/3/50

|

7.37

|

4” PT

|

1000

|

1800

|

2000

|

480

|

R407c

|

16

|

|

CDK-350CA

|

48

|

1695

|

380/3/50

|

7.96

|

4” PT

|

1000

|

1800

|

2000

|

520

|

R407c

|

16

|

|

CDK-400CA

|

61

|

2154

|

380/3/50

|

9.55

|

5” PT

|

1000

|

1800

|

2000

|

580

|

R407c

|

16

|

Technical Specifications: CDK-CA | Water Cooled

|

MODEL

|

Air Flow

|

Power Supply

|

Nominal

|

Connection |

Dimension (mm)

|

Weight

|

Refrigerant

|

Pressure

|

| (m³/min) |

(CMF) |

V/PH/Hz

|

Power (kw)

|

inch |

W.

|

L.

|

H.

|

Kg

|

Bar (max)

|

|

CDK-100CW

|

15

|

530

|

380/3/50

|

2.06

|

2-1/2” PT

|

450

|

1200

|

1350

|

165

|

R407c

|

16

|

|

CDK-125CW

|

18

|

636

|

380/3/50

|

2.5

|

2-1/2” PT

|

450

|

1200

|

1350

|

198

|

R407c

|

16

|

|

CDK-150CW

|

23

|

812

|

380/3/50

|

2.85

|

2-1/2” PT

|

450

|

1200

|

1350

|

208

|

R407c

|

16

|

|

CDK-175CW

|

28

|

989

|

380/3/50

|

3.3

|

2-1/2” PT

|

450

|

1200

|

1350

|

225

|

R407c

|

16

|

|

CDK-200CW

|

30

|

1059

|

380/3/50

|

3.95

|

3” PT

|

600

|

1200

|

1600

|

256

|

R407c

|

16

|

|

CDK-250CW

|

36

|

1271

|

380/3/50

|

4.27

|

3” PT

|

600

|

1200

|

1600

|

380

|

R407c

|

16

|

|

CDK-300CW

|

43

|

1519

|

380/3/50

|

4.6

|

4” PT

|

600

|

1200

|

1600

|

400

|

R407c

|

16

|

|

CDK-350CW

|

48

|

1695

|

380/3/50

|

6.27

|

4” PT

|

600

|

1200

|

1600

|

450

|

R407c

|

16

|

|

CDK-400CW

|

61

|

2154

|

380/3/50

|

6.86

|

5” PT

|

650

|

1204

|

1350

|

510

|

R407c

|

16

|

|

CDK-500CW

|

72

|

2543

|

380/3/50

|

8.05

|

5” PT

|

650

|

1204

|

1350

|

930

|

R407c

|

16

|

|

CDK-600CW

|

89

|

3143

|

380/3/50

|

10.3

|

6” PT

|

800

|

1500

|

1900

|

1050

|

R407c

|

16

|

|

CDK-700CW

|

96

|

3390

|

380/3/50

|

12.3

|

6” PT

|

800

|

1500

|

1900

|

1120

|

R407c

|

16

|

|

CDK-800CW

|

122

|

4308

|

380/3/50

|

13.75

|

6” PT

|

800

|

1800

|

1900

|

1260

|

R407c

|

16

|

|

CDK-1000CW

|

144

|

5085

|

380/3/50

|

18.25

|

8” PT

|

800

|

1800

|

2000

|

1580

|

R407c

|

16

|

|

CDK-1200CW

|

170

|

6004

|

380/3/50

|

20.6

|

8” PT

|

1200

|

1800

|

2000

|

1860

|

R407c

|

16

|

|

CDK-1500CW

|

185

|

6533

|

380/3/50

|

24.6

|

10” PT

|

1200

|

1800

|

2000

|

2290

|

R407c

|

16

|

|

CDK-2000CW

|

285

|

10065

|

380/3/50

|

36.5

|

12” PT

|

1200

|

2400

|

2100

|

2400

|

R407c

|

16

|

|

CDK-2500CW

|

340

|

12007

|

380/3/50

|

41.2

|

12” PT

|

1200

|

2400

|

2100

|

2890

|

R407c

|

16

|

- CDK-CA & CDK-CW Series Air Inlet Temperature 80 ˚C (Max.)

- Dew Point Temperature 3 - 10 ˚C

- Ambient Temperature 5 - 43 ˚C (Max.)

- CDK-CA & CDK-CW Series with After Cooler

- Air In-Out Pressure Drop < 3 Psig

- 2 Years warranty for Compressor and Evaporator

Dryer maximum air flow = Dryer air flow x K1 x K2 x K3 x K4

|

Correction factor

|

|

Ambient temperature ˚C

|

28

|

30

|

32

|

35

|

38

|

40

|

42

|

43

|

|

Factor (K1) CDK-CA

|

1.14

|

1.1

|

1.06

|

1

|

0.94

|

0.91

|

0.88

|

0.86

|

|

Air inlet temperature ˚C

|

45

|

50

|

55

|

70

|

80

|

-

|

-

|

-

|

|

Factor (K2)

|

1.2

|

1.1

|

1

|

0.91

|

0.83

|

-

|

-

|

-

|

|

Working pressure Kg/cm²

|

4

|

6

|

7

|

8

|

9

|

10

|

13

|

16

|

|

Factor (K3)

|

0.79

|

0.94

|

1

|

1.05

|

1.09

|

1.12

|

1.2

|

1.26

|

|

Dew point temperature ˚C

|

-

|

3

|

4

|

5

|

6

|

7

|

8

|

10

|

|

Factor (K4)

|

-

|

0.96

|

1

|

1.02

|

1.03

|

1.06

|

1.07

|

1.09

|

|

Water temperature ˚C

|

25

|

26

|

28

|

30

|

32

|

34

|

36

|

37

|

|

Factor (K1) CDK-CW

|

1.14

|

1.1

|

1.06

|

1

|

0.94

|

0.91

|

0.88

|

0.86

|