There are two kinds of Oil-free screw air compressors: water-lubricated screw type and dry oil-free type. The gas compression process of an oil-free screw air compressor does not involve lubricating oil. For the water-lubricated screw air compressor, the pure water is the lubricating medium instead of oil, has lubricating, cooling, sealing, denoising function. For the dry oil-free air compressor, there is no lubricating medium.

Structure

The twin-screw(or double-screw) oil-free air compressor is a high-speed air compressor. It uses two mutually meshing screws for relative rotation to compress air. The twin-screw cylinder is equipped with two screws. One with four convex teeth is called an automatic rotor (also called a male rotor). The other with six concave teeth (also called a female rotor) is a driven rotor. The rotors are all helical. The male and female rotors mesh with each other for reverse operation. The two ends of the rotor are equipped with bearings. A sealed space is formed between the tooth grooves of the rotor and the cylinder. Two ends of the rotor are provided with intake and exhaust ports.

Principle

1. Air Suction

Firstly, the air enters the volume between the teeth of the rotors through the air filter. As the rotor rotates, the volume between the two teeth continuously expands. When these two volumes reach the maximum, the inter-tooth volume is disconnected from the suction orifice. The suction process ends.

2. Air Compression

The rotors continue to rotate, forming a V-shaped inter-tooth volume pair. As the teeth squeeze into each other, their volume gradually decreases. Then the air is compressed. This process continues until the inter-tooth volume pair communicates with the exhaust port.

3. Air Exhaust

When the enclosed volume between the teeth communicates with the exhaust port of the casing, the compressed air starts to be discharged. As the volume between the teeth shrinks, the compressed air is gradually discharged exhausting. This process continues until the profile line at the end of the tooth is fully engaged. At this time, the air in the interdental volume is completely exhausted through the exhaust port.

The twin-screw oil-free air compressor has the advantages of compact structure, small volume, and reliable work. But compared with the water-lubricated screw air compressor, the operation temperature is higher, and need two-stage compression and cooling.

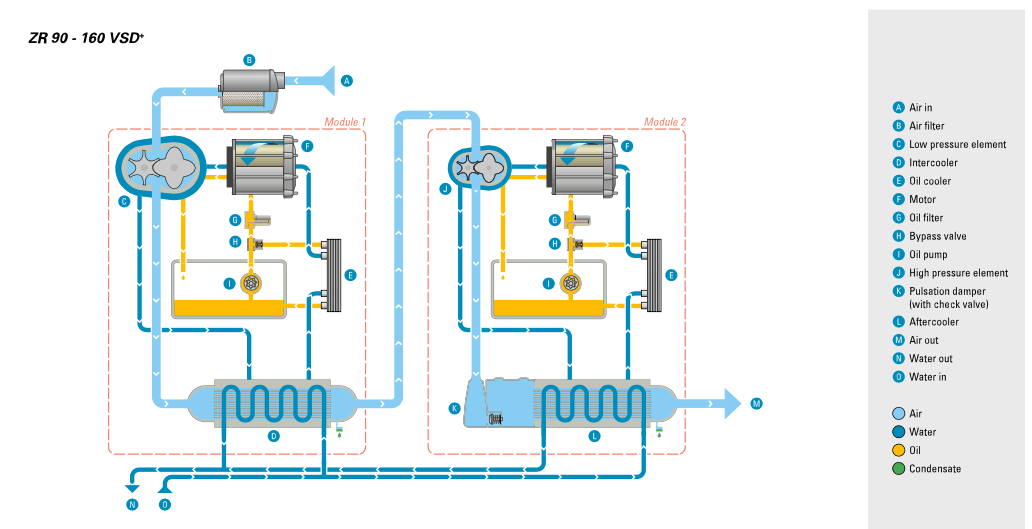

Flow charts

Note: the pictures are from Atlas Copco air compressor.