The air compressors are further divided into many categories based on their functionality but here in this article, we discuss the most significant and common types.

The below crafted profound list will for sure help you to make an effortless decision for choosing the best air compressor type. So, take a thorough reading tour and make your verdict.

Rotary Screw Compressors

Rotary screw compressors have demand in commercial, industrial, and light manufacturing applications that have the power capacity range of 3 hp to 500 hp. Rotary screw compressors function compatible with the principle of positive displacement. It procures a pair of helical and spiral screws that spin smoothly and direct the air into the pressure chamber. It offers much higher efficiency but it requires very low maintenance and very little energy to carry out the operations. This is the reason, it has more market demand than the other screw compressors. These types of compressors are used by automated manufacturing and food packaging plants.

There are further four types of rotary screw compressors, but initially, we discuss the single screw compressors and twin-screw compressors:

Single screw compressors:

These compressors typically entail a single set of rotors. And it functions directly through the gears and shaft of the motor. It is also driven with the help of a belt or pulley arrangement. It operates with more force and does not create a sharp noise.

Twin-screw compressor

This type of compressor consists of two sets of rotors that are positioned in the stator housing. This type of screw compressor may have two crafted proposals, over/ under design, or end-to-end design. It has a high manufacturing cost.

Oil-free screw compressors

These compressors do not necessitate any kind of friction or lubrication in which the rotor needs oil. So, in this compressor, the gas or the pressurized air remains oil-free and is used by most of the industries that do not abide contamination. Some of the oil-free compressors use water for maintaining the temperature and making it cool.

Oil-lubricated screw compressors:

In these compressors, oil is required to keep all the parts lubricated. It also controls the temperature limit. It also minimizes any kind of leaks through the chamber during discharge. Once you use the compressor, it will re-filtered the oil before using it the next time.

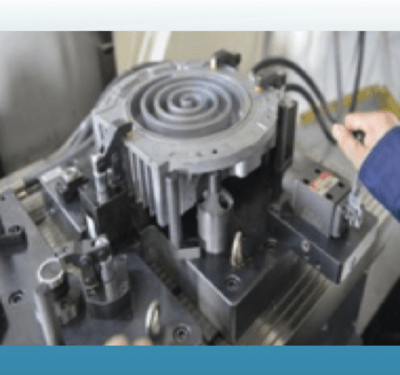

Scroll Compressors

The scroll compressor consists of two spiral scrolls. One is in motion and the other is fixed and attached to the body of the compressor. The fixed scroll directs the moving path of the motion scroll and thus it rotates around it.

When the scroll rotates, the gas pockets are continuously formed as a result of this movement. Initially, it goes into the outer of scrolls, then slowly it moves to the center, from where the gas is discharged. When this gas is rooming around the spirals, it will not only increase the temperature but the pressure is also increased.

Talking about its structure, it usually comes in the cylindrical shell welded with steel and is called a numeric. It does not necessitate any kind of discharge or suction valves. It only requires the high dynamic valves that operate in high pressure. These compressors are very light in weight as compared to bulky compressors.

Reciprocating/ Piston Compressor

Reciprocating compressors are the most vital compressors that fall under the category of positive displacement compressors. Reciprocating compressors are generally called the piston compressors because it consists of the piston where the air is compressed. The gas or air crosses in the rotary piston where it is compressed due to continuous forward and backward motion.

It has a very meek, elegant design and is able to move in both rotary and linear commands. The functioning principle is also very easy to understand. To start up the operation, it requires a gas or diesel engine, you can also use an electric motor. You can simply turn on the switch and the motor begins to function. The shaft associated with the pistons starts moving to and fro. In this way, the air is compressed in the suction cylinder and moves to the discharge valves. Once this procedure finalizes, it repeats again and again.

Centrifugal Compressor

Centrifugal compressors are somehow diverse from regular compressors. It is a type of mechanical expedient that works with the assistance of radial acceleration and thus compresses a fluid. It is also stated as the radial compressor as the gas or the air enters the rotor axially and then discharges radially.

Talking about its structure, it comprises different parts including, outlet, diffuser, impeller or rotor, casing, rotor blades, suction valves, and discharge valve. All these parts have vigorous functioning in compressing the fluid.

After turning the compressor on, the air is firstly inflowing into the air tank then it goes to rotor or impeller, from there it then strikes to rotor blade, these blades then procure the kinetic energy which then increases the speed. It then passes to the diffuser from where it goes to the discharge valve and then discharges out. These types of compressors are used in automotive engines, gas turbines, chemical plants, oil refineries, etc.

So to sum up, we can say that the above-crafted artifact has all the necessary details about the different types of compressors including rotary compressor, scroll compressor, reciprocal compressor, and centrifugal compressors. So we anticipate that after reading this fashioned article, all your compressors-related interrogations are vacant and now you can easily opt for the best compressors of your choice.