Scroll compressors require very little maintenance as compared to other air compressors, making them easy to maintain expediently. Apart from the low maintenance, it tosses a very high-efficiency rate making it a more premium compressor type. Scroll-type air compressors also fall under the category of oil-free compressors, as there is no oil usage even in the gearbox; thus, no leakage of oil occurs.

Scroll or spiral compressors usually come in the market with very little weight as they have a very small size, which provides convenience to the user in handling. Scroll air compressor has one very unique feature; it also works as the scroll expander when it functions in reverse or opposite rotation, thus providing mechanical work while expanding compressed air, gas, or fluid.

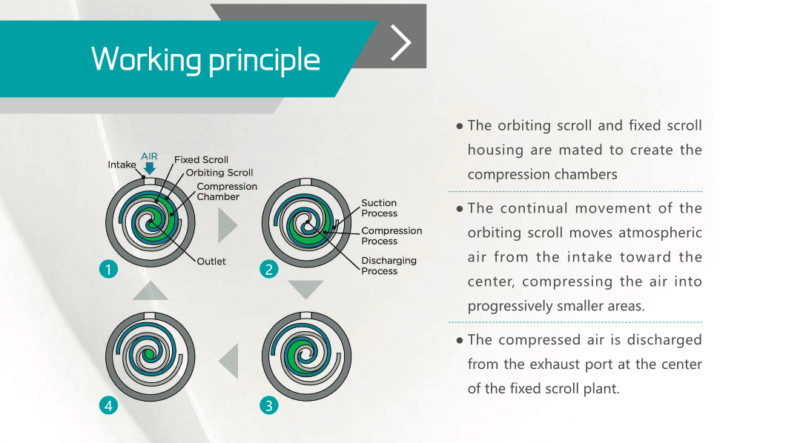

Working Principle of Scroll Air Compressor

The working of scroll air compressors occurs in relatively three phases. When the moving scroll is rotated around the stationary scroll, the gas pockets are formed, and thus the air gets trapped in these pockets, which then further passes to the below discussed three phases.

Suction phase:

In this first shaft revolutionary phase, the motion scroll moves around the orbit of the fixed spiral; as in result, it creates the gas pockets. And when the gas pocket is formed, the suction port endows the outside air to get in a trap with these air spaces or gas pockets. When the first rotatory revolution is completed, the adjacent surfaces meet at the ends so that the air can’t move outside.

Compression Phase:

This is the second shaft revolutionary phase; in this phase, the rotatory scroll again starts moving around the fixed scroll. As the air is sealed in the gas pockets, further motion causes the air to move to the inner gas pockets and in turn, the volume of the air is reduced and the air gets compressed. When this second phase completes, the maximum gas is compressed in the gas pockets.

Discharge phase:

This is the third shaft revolutionary phase; in this phase, the compressed gas which is present at the most inner pockets moves toward the discharge port with the help of further motion of scrolls. The compressed air then discharges out through the port which results in making the volume in gas pockets condensed to zero.

Once this procedure cycle completes, the three phases, namely suction phase, compression phase, discharge phase, again transpire instantaneously at comparative sequence.

Parts for Scroll Air Compressor

Talking about its structural parts, it consists of the steel welded cylindrical shell, where the compressor shell is enclosed. This is the reason these scroll air compressors are called fully hermetic compressors.

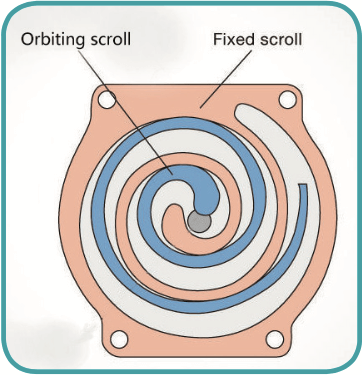

A single scroll type air compressor ponders two spiral or scrolls. From these two scrolls, one is attached or fixed to the body of the compressor, and the other is in continuous motion. The scroll, which is fixed to the body basically provides a motion pathway to the moving scroll. The moving scroll rotated around the orbit of the fixed scroll. The motor shaft and discharge port are also contrasted that carries the operation.

In most compressors, the suction or discharge valves are used, but these scroll compressors don’t work on these suction valves; rather, they use the most efficient dynamic valves that also operate the compressor at a very high differential pressure rate. Thus, these dynamic valves also aid in increasing the functioning efficiency of these scroll compressors. Apart from the other compressors, this scrolls compressor does not have a piston to compress the air.

Advantages of Scroll Compressors

- Due to the absence of a piston, the scroll air compressor endows the 100% compression of gas, thus reducing the cost of energy.

- As it only has few moving parts, thus it helps the compressor to work quietly without making any sharp noise.

- Due to less noise and vibration, it does not require the suspension of springs.

- Having few parts and less friction also make the compressor more durable.

- It has considerably less weight as compared to other compressors, making it easy to handle.

- Scroll-type air compressors work very efficiently at all types of duty cycles, whether it of low duty or high duty.

- It tosses a very high energy productivity ratio.

- The three working phases occur simultaneously, thus the flow of gas is very smooth which progressively reduces the gas pulsations.

- It proves very beneficial for cleaning purposes, as it contains no oil that makes it contamination-free.

Applications of Scroll Compressors

- Scroll air compressors have vital use in all field systems of air conditioning. They are also used in the household conditioning sector as they produce very low noise. Moreover, it also proves very beneficial for commercial conditioning purposes.

- Other than air conditioning purposes, these compressors are also used in laboratories. As laboratories require a small or noise-free compressor, it would be the best option because scroll air compressors are ultra-quiet.

- It also offers wide use in the refrigeration of food and fruits.

- Hospitals and medical centers also use these scroll compressors.

- It is also used in water cleaning equipment as it is oil-free, so it carries out the cleaning purpose more effectively without any contamination.

- Other than the above applications, these scroll-type air compressors have found a wide range of applications in heat pumps, vacuum pumps, transportation of trucks, and naval containers.

On a final note, we can articulate that the above-fabricated article encompasses all the momentous details about the scroll-type air compressors. All this information is contrived after thorough groundwork. So before buying any compressor, you ought to peruse this comprehensive article; it will for sure lead you to buy the best compressor.