A group of experts, dedicated to developing turbo machinery for more than 20 years, leads and manages TyPhoonCompressor. The company expands the horizon of next-generation environmental industry with direct-coupled and eco-friendly turbo technology. Our products utilize highly efficient energy saving oil-less Air Foil Bearing technology. TyPhoonCompressor's diverse product portfolio will provide the best solution for your municipal or industrial air supply needs. Our turbo machines are a harmonization of extensive R&D experiences and ingenious patented technology. We serve more than 2 billion people in more than 70 countries around the world.

DIVERSE Key Application Areas

WATER

Sewage / Wastewater Treatment Plant

Aeration blowers associated with the biological treatment of effluent within municipal sewage treatment plants

Downstream Control

Bioactive Response System (BARS) is a Fully-automated, highly efficient control system that optimizes the operation of aeration turbo blowers

MINING

Iron Production

Blast furnace air blowers for reaction (hot blast) and combustion air applications

Metal Refining

Aeration, oxidation and combustion air blowers for biological and conversion processes

Metal Smelting

Oxidation air blowers for smelting processes

INDUSTRIAL

Carbon Black

Blowers providing combustion air for the associated furnaces

Effluent Treatment

Aeration blowers associated with the biological treatment of effluent within industrial plants

Fermentation

Air blowers associated with biochemical fermentation within pharmaceutical and yeast production markets

Mechanical Vapor Recompression

Air blowers used to recompress vapor generated during an evaporation process so that it can be used as the heating medium for the same evaporation process

POWER

Circulating Fluidized Bed Combustion

Blowers providing fluidizing air within the loop seal system on a circulating fluidized bed

Flue Gas Desulphurization

Oxidation air blowers associated with the cleaning of flue gases produced within power and heavy industrial plants

PETROCHEMICAL / REFINING

Fertilizer Production

Blowers / Compressors providing atomizing air for fertilized bed

Sulphur Recovery Units

Blowers/compressors providing reaction air for the catalytic recovery of Sulphur within refineries and gas processing facilities

UNBELIEVABLE Reduce your energy costs and Save your precious $$$

Low Vibration Under 1.0 mm/s

Low Noise Under 80dB ± 3dB

Only air filter changes required

OVERWHELMING Core of Excellence

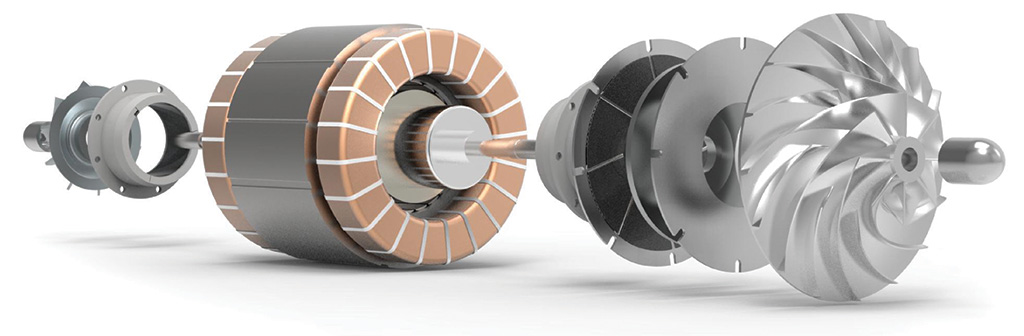

1. Inlet of Motor Cooling Air

1. Inlet of Motor Cooling Air

2. Permanent Magnet Motor

3. Air Foil Bearing

4. Impeller

5. Parameter Sensing System

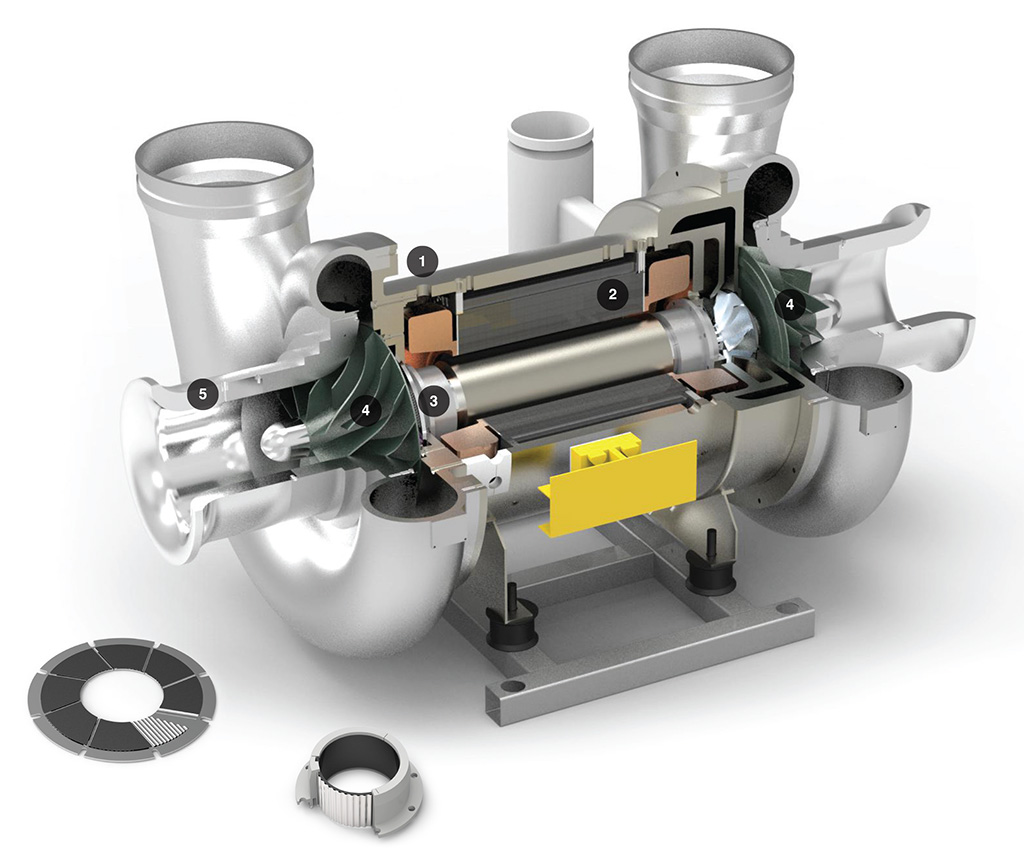

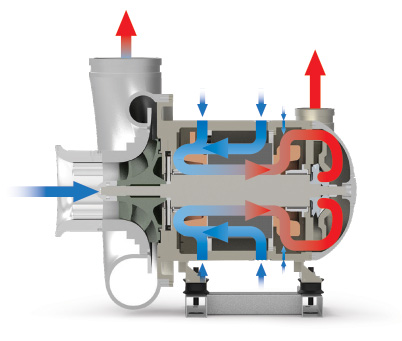

The above image illustrates cooling path in a single impeller core. The cutaway image below shows the assembled components of a dual impeller core

The above image illustrates cooling path in a single impeller core. The cutaway image below shows the assembled components of a dual impeller core

1

MOTOR COOLING SYSTEM

PATENT # : 10-1580877 / 10-1607492

TyphoonCompressor's motor cooling system has a patented two-stage cooling structure that can lower the motor temperature more than 10 degrees compared to other brands. The air cools stator, bearing, winding and rotor. The heated air is exhaused outside of the enclosure.

2

HIGH EFFICIENT

PERMANENT MAGNET MOTOR

TyphoonCompressor PM motor is a high efficient (95%), self-designed and manufactured product, which can perform at ultra-high speed ranging from 20,000 to 150,000 RPM.

3

HIGH PERFORMANCE IMPELLER

TyphoonCompressor’s impeller is an in-house designed and manufactured product. It guarantees high-efficiency with same quality all the times. It is made of high strength aluminum alloy (AL7075-T651) that is precisely processed up to 0.001mm thickness.

Our impeller with. hard anodizing on the surface has an excellent corrosion and chemical resistance, so it has an excellent performance in hostile environments. Turbowin also provide stainless steel and titanium impellers.

The image on the left shows air foil bearing’s physical condition after 100,000 times of on/off tests.

The image on the left shows air foil bearing’s physical condition after 100,000 times of on/off tests.

4

AIR FOIL BEARING

PATENT # : 10-1632356 / 30-0858674

The frictionless characteristic of our oil-less air foil bearing makes it extremely durable. Our bearing has passed On/Off testing of over 100,000 cycles.

5

ON-MACHINE REAL TIME PARAMETER MEASUREMENT

PATENT # : C-2016-006451

The control system, which measures pressure, temperature, and flow rate in real time, controls the VFD and BOV quickly and precisely. Our bell-mouth flow meter can measure the flow within ± 0.5% tolerance (JIS B 8340).

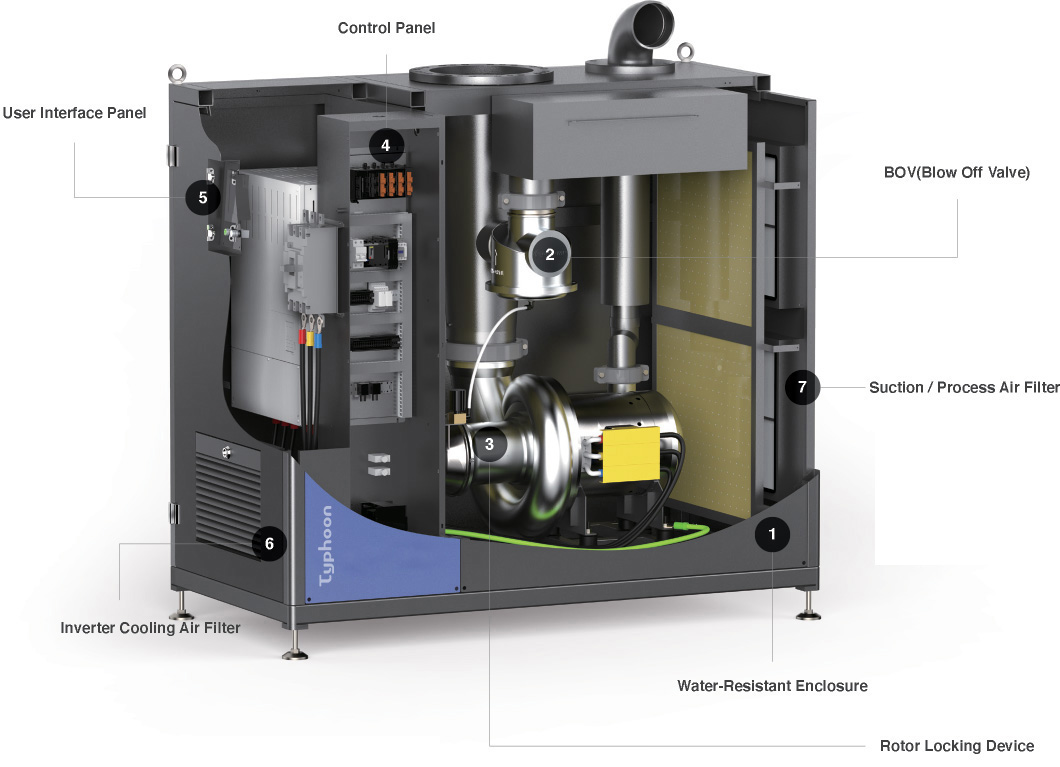

OUTSTANDING Simplified Structure

1. Water resistant enclosure PATENT # : 10-1616274

Patented water resistant enclosure for outdoor applications, a simple overhead canopy and covers on inlet louvers are often all that is required.

2. BOV(Blow Off Valve) PATENT # : 10-1651589

The BOV protects the core from surge during operation and in emergency circumstances. Our patented BOV has a unique design that is operated by internally generated differential pressure without supply of external compressed air.

3. Rotor Locking Device PATENT # : 10-1791977

All TyphoonCompressor machines are shipped with our patented rotor locking device. This is to minimize any damage during transportation and installation period.

4. Control Panel

The Control Panel can utilize either a PLC or MICOM controller, based on the customers preference. For the PLC option, we can offer any of Allen-Bradley, SIEMENS, RS-AUTO or LG. The control panel can be connected remotely to plant SCADA via Ethernet, RS485 or RS422.

5. User Interface Panel

All TyphoonCompressor control systems use either a 7 or 10 inch touch screen so that users can easily and precisely control operational targeting values and control parameters . Four operation switches (RUN, LOAD, STOP, EMERGENCY) allow proper operation during normal and emergency conditions.

6. VFD Cooling System

TyphoonCompressor blowers use UL/CE certified VFD from well known industry suppliers to run the high-speed motor. VFD Cooling Air can be either passed from the electrical compartment into the core compartment (Type A), or it can be ducted to the outside of the enclosure (Type B). The image to the right depicts the Type A cooling system.

7. Suction / Process Air Filtering System

Intake air passes through a non-woven free-filter and a pleated main air filter (combined minimum efficiency 85%) to effectively remove potentially harmful contaminants. The filter can be replaced easily even during operation.

TROUBLE-FREE & SAFE No Matter How Complex

TWO YEARS GUARANTEE

EXTREMELY LOW VIBRATION (BELOW 1.0 MM/S)

LOW NOISE (UNDER 80dB +/- 3dB)

100% OIL-FREE (ECO-FRIENDLY)

PLC CONTROL AND SCADA INTERFACE (INTEGRATED CONTROL FOR REMOTE MONITORING AND OPERATION)

HIGH SPEED VFD (VARIABLE SPEED DRIVER) CONTROL

EASY OPERATION AND MAINTENANCE

RELIABLE GLOBAL REFERENCE WITH STRONG CUSTOMER SATISFACTION

More than 2 Billion People in 70 Countries benefit from our machine

WIDE Product Range

1. WL SERIES Single Impeller Series

|

Featured Model

WL30-08

|

|

Flow

|

5~160 m3/min

|

WL single impeller series are small, efficient and durable turbo blowers. These blowers can be used for air supply in water and wastewater treatment plants, dry powder transfer in chemical or cement plants, air knife and numerous other industrial applications. These single impeller machines are the best solution for low to medium air volume, low pressure requirements.

|

|

Pressure

|

0.4~1.2 bar

|

|

Noise

|

80dB ± 3dB

|

|

RPM

|

24,000 ~ 55,000

|

TURBO BLOWER WL SERIES 10~1000HP [0.4~1.2 BAR]

WL10

WL20

WL30

WL40

WL50

WL75

WL100

WL125

WL150

WL200

| SPECIFICATION |

|

WL10 |

WL20 |

WL30 |

WL40 |

WL50 |

WL75 |

WL100 |

WL125 |

WL150 |

WL200 |

WL250 |

| |

DISCHARGE

PRESSURE (mmAq) |

Single Impeller Type

Condition : 1 atm, 20°C, 65% RH, Tolerance of air flow rate ±5% |

| AIR FLOW RATE (m3/min) |

4,000 |

|

|

28 |

37 |

47 |

70 |

100 |

115 |

130 |

- |

- |

| 6,000 |

7 |

14 |

20 |

25 |

34 |

51 |

69 |

82 |

105 |

140 |

160 |

| 8,000 |

5 |

11 |

17 |

22 |

28 |

42 |

55 |

70 |

84 |

109 |

135 |

| 10,000 |

- |

- |

14 |

18 |

21 |

34 |

45 |

55 |

65 |

87 |

104 |

| 12,000 |

- |

- |

- |

- |

18 |

28 |

38 |

47 |

57 |

75 |

93 |

| SHAFT POWER (hp) |

|

10 |

20 |

30 |

40 |

50 |

75 |

100 |

125 |

150 |

200 |

250 |

| EXHAUST PIPE (mm) |

4,000 |

|

|

150A |

150A |

200A |

250A |

300A |

300A |

300A |

- |

- |

| 6,000 |

80A |

100A |

125A |

150A |

150A |

200A |

200A |

200A |

300A |

300A |

300A |

| 8,000 |

80A |

100A |

125A |

150A |

150A |

200A |

200A |

200A |

250A |

300A |

300A |

| 10,000 |

- |

- |

100A |

125A |

150A |

150A |

200A |

200A |

250A |

250A |

300A |

| 12,000 |

- |

- |

- |

- |

125A |

150A |

150A |

200A |

200A |

250A |

250A |

| DIMENSION (mm) |

W |

650 |

650 |

650 |

700 |

700 |

850 |

850 |

850 |

900 |

900 |

900 |

| L |

1100 |

1100 |

1100 |

1,300 |

1,300 |

1,500 |

1,500 |

1,500 |

1,800 |

1,800 |

1,800 |

| H |

1000 |

1000 |

1000 |

1,100 |

1,100 |

1,400 |

1,400 |

1,400 |

1,650 |

1,650 |

1,650 |

| WEIGHT (kg) |

|

300 |

320 |

350 |

450 |

450 |

550 |

600 |

650 |

800 |

850 |

900 |

| BLOW OFF V/M |

|

40 |

50 |

50 |

65 |

65 |

125 |

125 |

125 |

125 |

125 |

125 |

| FUSE, BREAKER (Amphere) |

|

30 |

50 |

60 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

2. WL SERIES Twin Impeller, Twin core Series

|

Featured Model

WL300-08

|

|

Flow

|

114~540 m3/min

|

Turbowin's WL Twin Impeller / Single Core and Twin Impeller / Twin Core machines can be utilized for all of the same applications as the single impeller machines, but are suited to the larger volume, medium to high air flow ranges. The Twin Core machines are also well suited to applications where a wider turn-down range is desired with turn-downs of up to 4:1 compared to the standard 2:1 turndown of single core machines.

|

|

Pressure

|

0.4~1.2 bar

|

|

Noise

|

80dB ± 3dB

|

|

RPM

|

24,000 ~ 40,000

|

High Efficiency Turbo Machinary

HIGH SPEED MOTOR, CONTACTLESS AIR BEARING, VARIABLE SPEED AND DIRECT DRIVING

| SPECIFICATION |

|

WL200 |

WL300 |

WL400 |

WL500 |

WL600 |

WL700 |

WL800 |

WL1000 |

| |

DISCHARGE

PRESSURE (mmAq) |

WL200-WL500: Twin Impeller Type / WL600-WL1000: Twin Core Type

Condition : 1 atm, 20°C, 65% RH, Tolerance of air flow rate ±5%< |

| AIR FLOW RATE (m3/min) |

4,000 |

200 |

266 |

- |

- |

- |

- |

- |

- |

| 6,000 |

- |

210 |

272 |

320 |

420 |

420 |

475 |

640 |

| 8,000 |

- |

164 |

216 |

270 |

320 |

320 |

370 |

540 |

| 10,000 |

- |

133 |

172 |

208 |

260 |

260 |

300 |

416 |

| 12,000 |

- |

113 |

145 |

185 |

228 |

228 |

255 |

370 |

| SHAFT POWER (hp) |

|

200 |

300 |

400 |

500 |

600 |

700 |

800 |

1000 |

| EXHAUST PIPE (mm) |

4,000 |

400A |

500A |

- |

- |

- |

- |

- |

- |

| 6,000 |

- |

400A |

400A |

500A |

500A |

500A |

600A |

600A |

| 8,000 |

- |

400A |

400A |

400A |

400A |

400A |

500A |

600A |

| 10,000 |

- |

300A |

400A |

400A |

400A |

400A |

400A |

600A |

| 12,000 |

- |

250A |

300A |

400A |

400A |

400A |

400A |

500A |

| DIMENSION (mm) |

W |

1200 |

650 |

650 |

700 |

700 |

850 |

850 |

850 |

| L |

2200 |

1100 |

1100 |

1,300 |

1,300 |

1,500 |

1,500 |

1,500 |

| H |

2000 |

1000 |

1000 |

1,100 |

1,100 |

1,400 |

1,400 |

1,400 |

| WEIGHT (kg) |

|

1300 |

1500 |

1700 |

2000 |

3000 |

3000 |

3200 |

3500 |

| BLOW OFF V/M |

|

175 |

175 |

175 |

175*2 |

175*2 |

175*2 |

175*2 |

175*2 |

| FUSE, BREAKER (Amphere) |

|

400 |

500 |

630 |

800 |

500*2 |

500*2 |

630*2 |

800*2 |