A group of experts, dedicated to developing turbo machinery for more than 20 years, leads and manages TyPhoonCompressor. The company expands the horizon of next-generation environmental industry with direct-coupled and eco-friendly turbo technology. Our products utilize highly efficient energy saving oil-less Air Foil Bearing technology. TyPhoonCompressor's diverse product portfolio will provide the best solution for your municipal or industrial air supply needs. Our turbo machines are a harmonization of extensive R&D experiences and ingenious patented technology. We serve more than 2 billion people in more than 70 countries around the world.

DIVERSE Key Application Areas

INDUSTRIAL / POWER

APulp and paper, carbon black, printing, effluent treatment, fermentation, mechanical vapor recompression, etc.

Flue gas desulphurization, oxidation air and fluidized beds.

WATER AND WASTE WATER TREATMENT

Fine bubble or coarse bubble aeration, basin aeration, soil remediation, MBR/MBBR, deep aeration, grit chamber aeration, filter backwash and other biological treatment

VACUUM APPLICATION

Pharmaceutical, breweries, food and beverage production and other facilities needing clean and oil free environment.

PETROCHEMICAL

Sulfur recovery, sour gas, thermal oxidation or refinery tail gas.

MINING

Iron production, metal refining and metal smelting.

SEMICONDUCTOR

Oil free air compressor for semiconductor and electronic production.

UNBELIEVABLE Reduce your energy costs and Save your precious $$$

|

ENERGY

REDUCTION

|

|

Low Vibration Under 1.0 mm/s

Low Noise Under 75dB ± 3dB

Only air filter changes required

Routine maintenance required

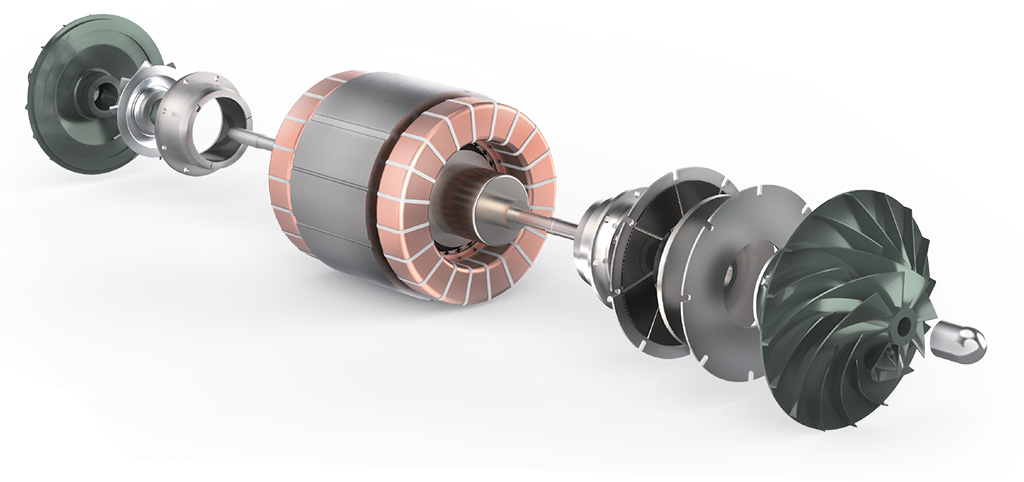

HIGH EFFICIENCY TURBO MACHINARY: MULTISTAGE AIR COMPRESSOR, HIGH SPEED MOTOR, CONTACTLESS AIR BEARING, VARIABLE SPEED AND DIRECT DRIVING